No products in the basket.

Bleeding

- Posted By : Bill

- Classroom Kits

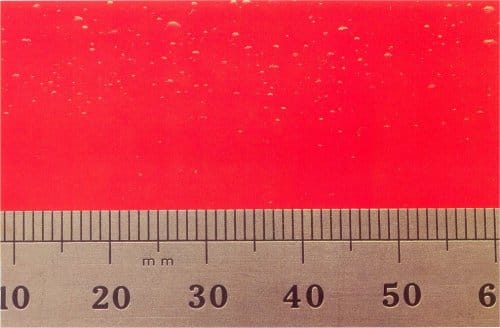

Cissing, Craters, Fish Eyes, Saucering

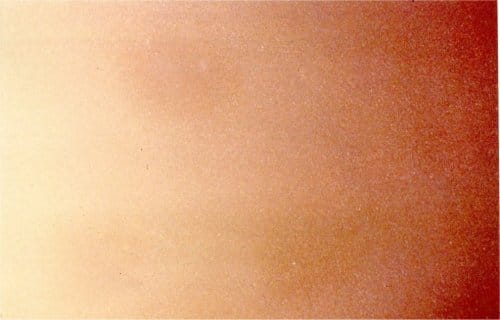

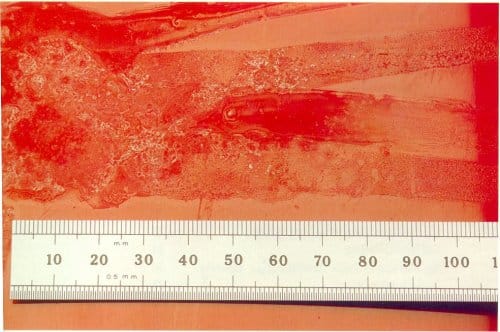

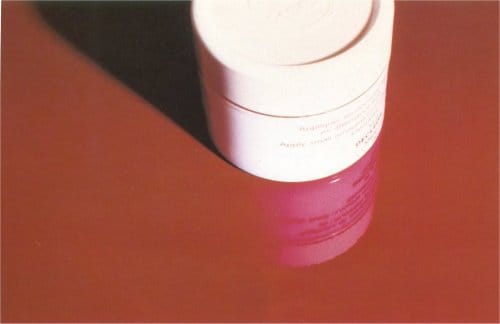

DESCRIPTION

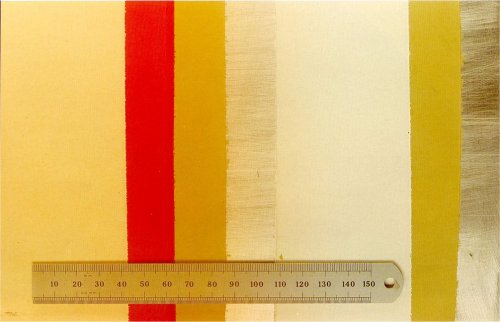

Discolouration of the topcoat, either in the form of a halo, or, in severe cases, a complete colour change. This defect usually only occurs when spraying over red or maroon paint.

CAUSE

Absorption of pigment from the underlying paint, dissolved by the solvents of the new coat.

PREVENTION

a) Test the original finish by spraying a small, flatted area.

b) Use an approved bleeding inhibitor sealant.

c) Remove any overspray from the surface before painting.

RECTIFICATION

Rub down to the original finish, seal with a recommended sealer and repaint.

After Drying

- Posted By : Bill

- Classroom Kits

Acid Attack

Bleaching

Blistering

Blooming

Blushing

Bridging

Bronzing

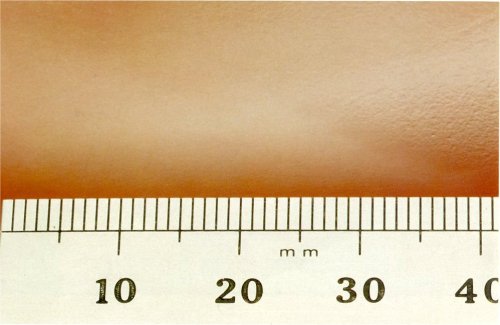

Chalking

Contamination

Corrosion

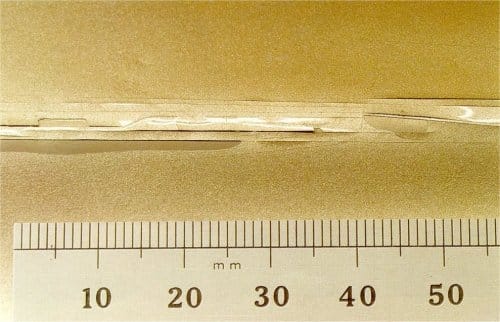

Cracking

Crazing

Dull Finish

Feather Edge Cracks

File Marks

Flaking

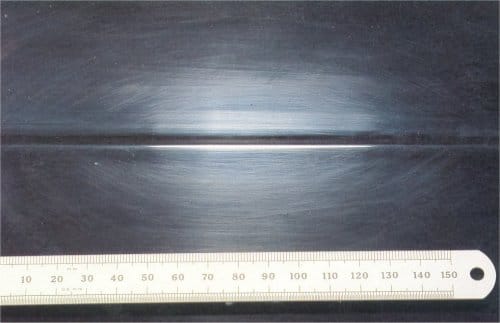

Mapping

Panel Faults

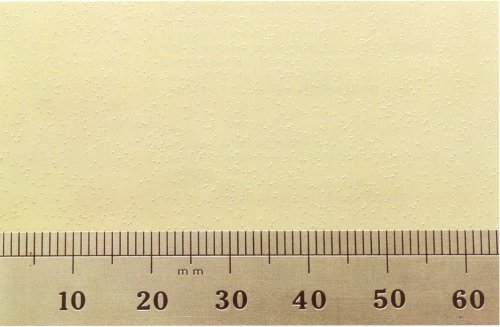

Pinholing

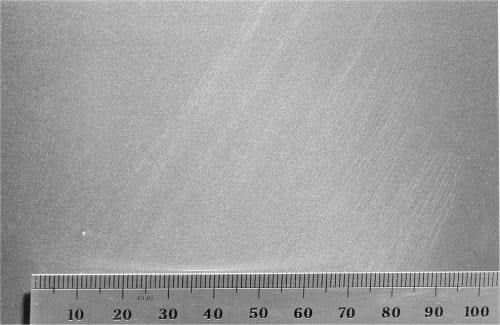

Polishing Marks

Poor Colour Match

Sanding Scratches

Solvent Popping

Stone Chips

Water Spotting

Wax Incorporation

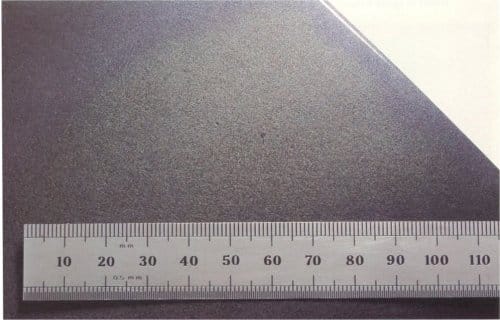

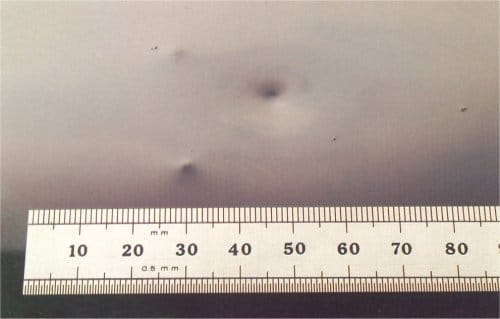

Contamination

- Posted By : Bill

- Classroom Kits

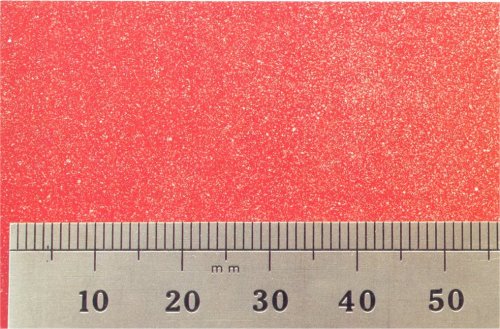

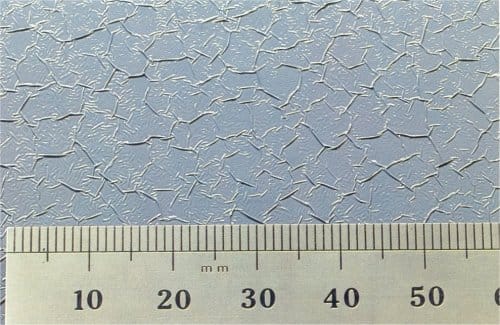

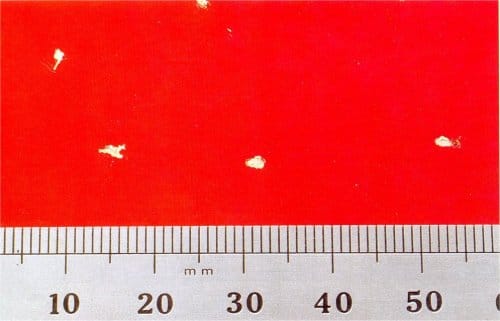

Airborne Contamination, Cement Dust, Contamination, Fall Out, Industrial Fallout, Rust Specs, Specs, Spots

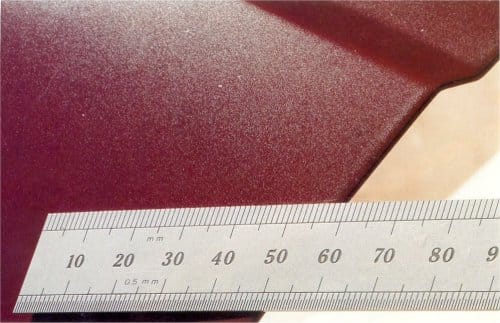

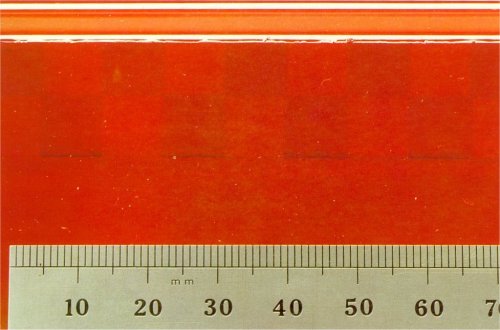

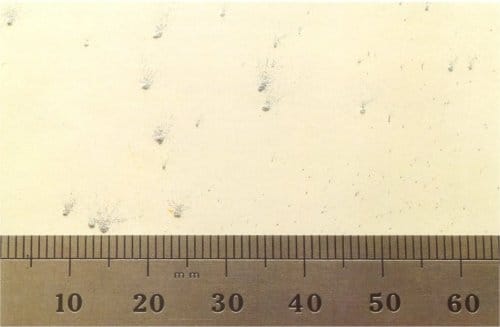

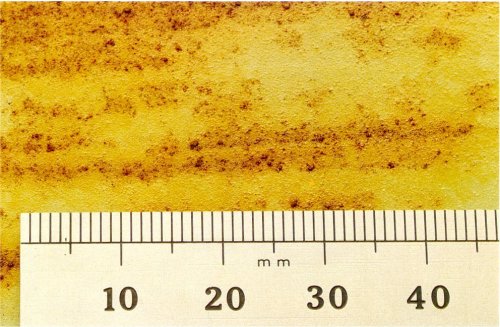

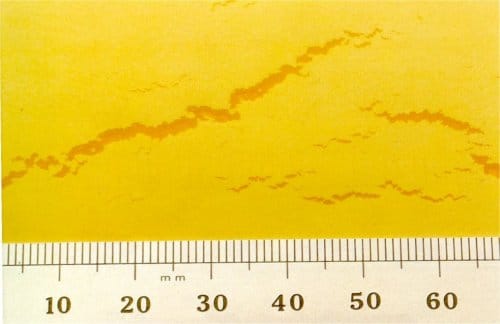

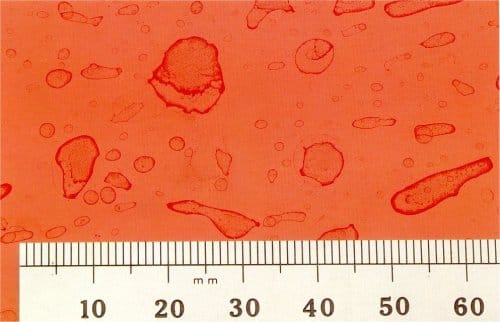

DESCRIPTION

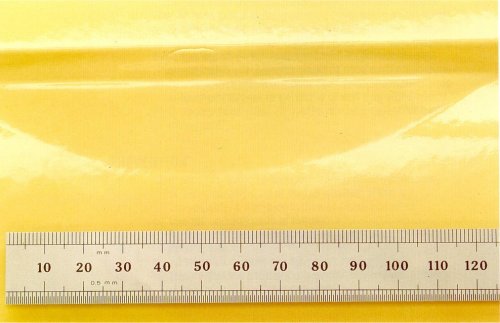

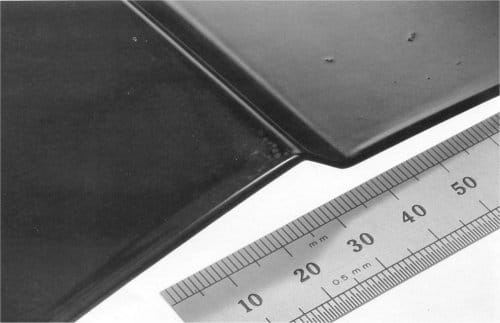

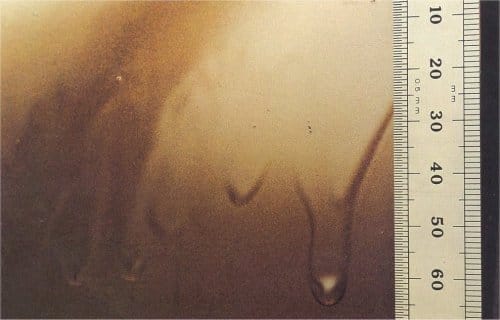

Spots, speckles or splash-like deposits on, or discolouration and staining of, the paint surface. The surface may have greasy or tacky spots, be coated with particles, or feel gritty.

CAUSE

Foreign substances or chemicals adhering to, or becoming embedded in the paint. Common sources are:

a) Tree sap and resins, wet leaves, berries, fruit or bird droppings allowed to remain on the paint.

b) Metallic particles becoming embedded in the surface of the paint and oxidising.

c) Salt deposits resulting from the evaporation of liquids on the surface. These may also lead to blistering.

d) Cement or other chemically active dust.

PREVENTION

a) Do not allow any deposits to remain on the paint surface.

b) Ensure the paint film is fully cured.

c) Store vehicles under cover and away from possible sources of contamination. Take special care not to expose new paint finishes to environments likely to cause contamination.

d) If an oven or drying room is used ensure that the filtration system is working properly, and that no industrial fumes enter the room.

RECTIFICATION

Light staining may be removed by washing the surface with a mild detergent solution, followed by washing with a 10% Oxalic acid solution to remove ferrous compounds. Rinse, compound and polish to restore the gloss. If discolouration and staining persist, rub down the surface and repaint.

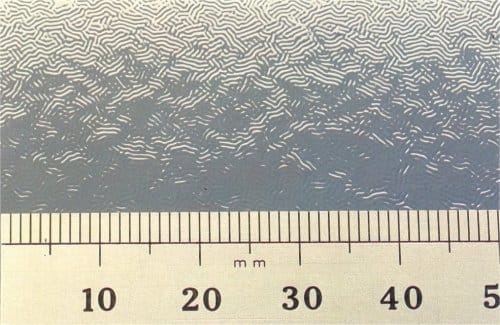

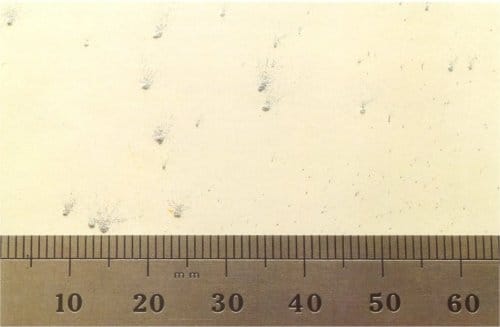

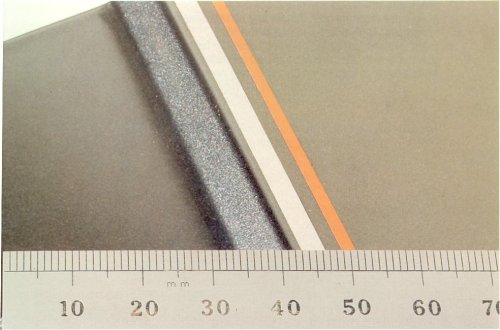

Mottle Effect – MaxMeyer

- Posted By : Bill

- Classroom Kits

MaxMeyer article on the mottle effect, explaining the patchy defect, causes and preventions, with a good bullet point summary of do’s and don’ts. Click the picture below to read the full article.

Reference: http://www.maxmeyerplus.co.uk

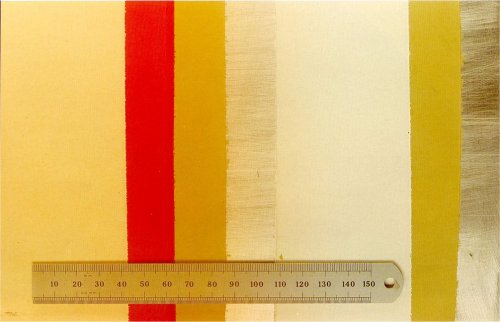

Preventing Re-works – MaxMeyer

- Posted By : Bill

- Classroom Painting, Classroom Kits

An efficient bodyshop puts quality into place to prevent re-works. Efficiency is not about cheaper products but about reducing waste, that is wasted time and materials when having to re-do the job again. Cheaper products can result in defects making the process more costly. Preventing problems and making sure the work flows without disruption or re-work is efficiency. Cutting down on costs can be counterproductive and lead to re-works or more time spent on rectification, whereas spending time and money on quality can be more profitable for your bodyshop. Read MaxMeyers tech tips on how you can prevent re-works. Click the picture below to read the full article.

Reference: http://www.maxmeyerplus.co.uk