No products in the basket.

MAXMEYER® Antistatic Agent Application

- Posted By : Bill

- Classroom Priming

Watch here for best practice application process for MaxMeyer Plastic Repair

MAXMEYER® Plastiprimer Application

- Posted By : Bill

- Classroom Priming

Watch here for best practice application process for MaxMeyer Plastic Repair

MAXMEYER® Plastic Cleaning before plastic priming

- Posted By : Bill

- Classroom Priming

Watch here for best practice application process for MaxMeyer Plastic Repair

Roberlo Multyfiller Express Fast Drying Primer Application

- Posted By : Bill

- Classroom Priming

High solid contents HS 4:1 acrylic filler. Excellent balance between covering and fast drying. This video enables you to quickly see the advantages of the product and to learn about some of the usage recommendations, thus enabling applications by technicians to be optimised. This demonstration is given by the Roberlo technical team who also monitored the educational quality of the final content.

Basic Assumptions – Must read

From start to finish, a guide on basics that must be covered when repairing and painting.

PPG Industries Automotive Refinish group makes these assumptions based on accepted industry practices,

our knowledge, past experience and feedback from our employees and customers. These assumptions are

intended to be used by collision repairers for reference and support documentation to promote a better

understanding of the refinishing process to their customers.

Norton Best Practice – Masking

- Posted By : Bill

- Classroom Priming

| Peter Klutt, host of Dream Car Garage, shows the best ways to protect a vehicle during the painting process with Norton masking products. |

|

|

| Reference: http://www.nortonautomotive.com |

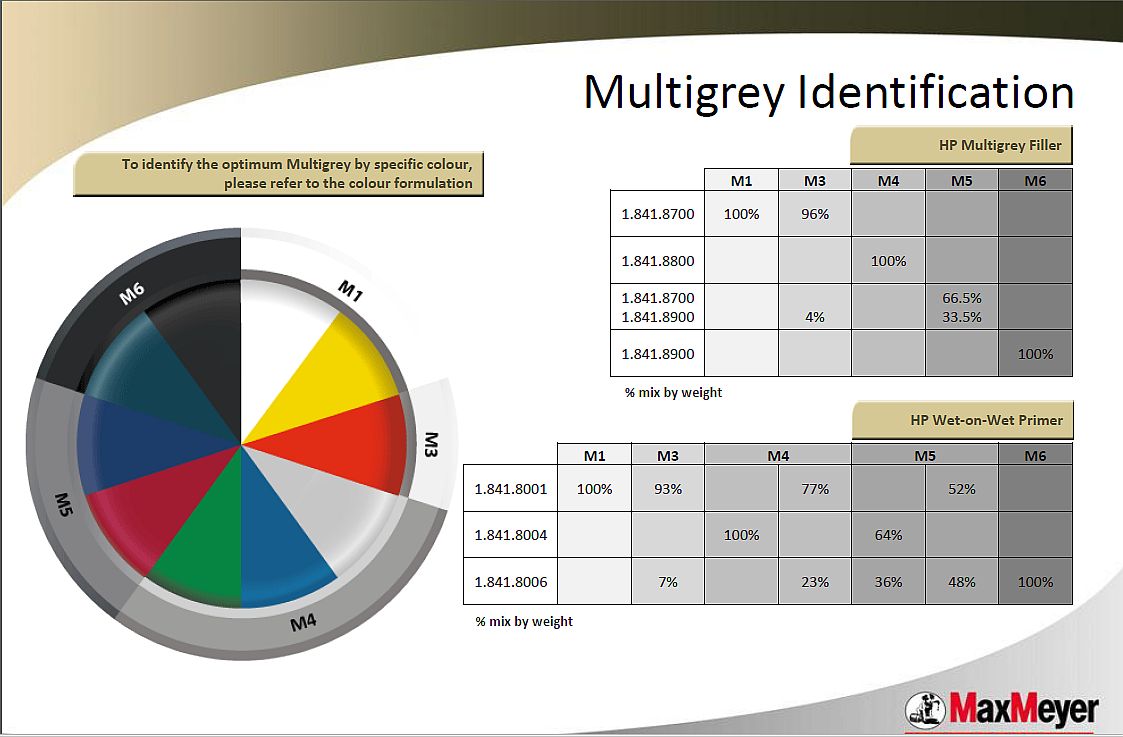

MaxMeyer MultiGrey Concept

- Posted By : Bill

- Classroom Priming

|

The MaxMeyer MultiGrey system is a range of grey shades available in the MaxMeyer Primer System, designed to allow you to use the correct grey shade for the colour including MultiGrey filler and wet on wet primer. |

|

|

|

|

|

Reference: http://www.maxmeyerplus.co.uk/ |

Etch Primer – The key to a great repair

- Posted By : Bill

- Classroom Priming

| MaxMeyer TechTalk on Etch primer, understanding why an etch primer should be used. Click the picture below to read the full article. |

|

|

| Reference: http://www.maxmeyerplus.co.uk/ |